Engineering the Backbone: Busbar & Enclosure Design of 800V LT ACDB Panels

When it comes to MW-scale solar panels operating at 800V, durability isn’t just a feature—it’s a design philosophy. At Accu-Panels, the busbar system and enclosure architecture are engineered not merely to house components, but to command performance, withstand punishment, and enable precision fault response for Busbar & Enclosure Design of 800V LT ACDB Panels

This isn’t about what’s inside the box—it’s about what makes the box last, perform, and protect your solar investment for decades.

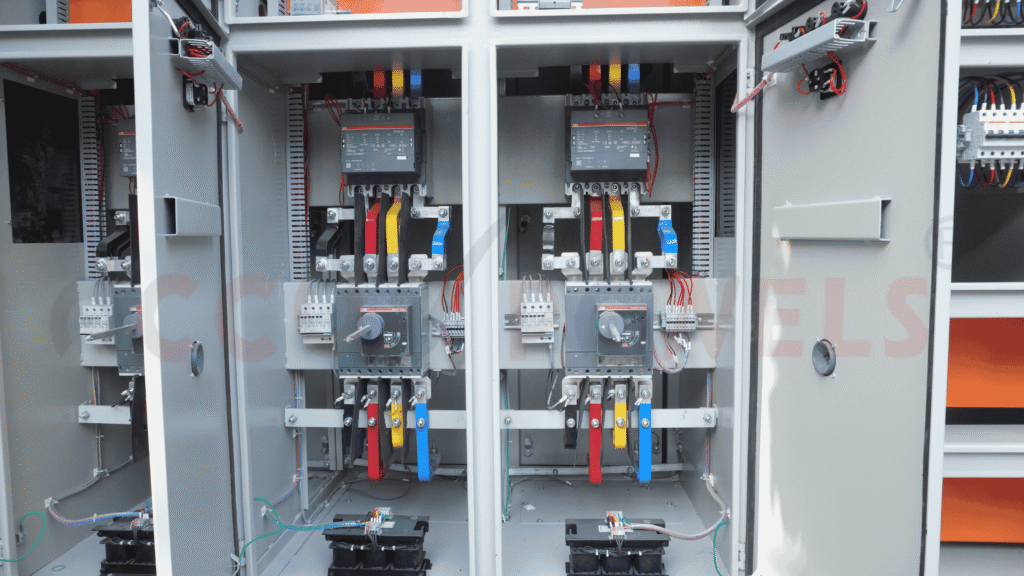

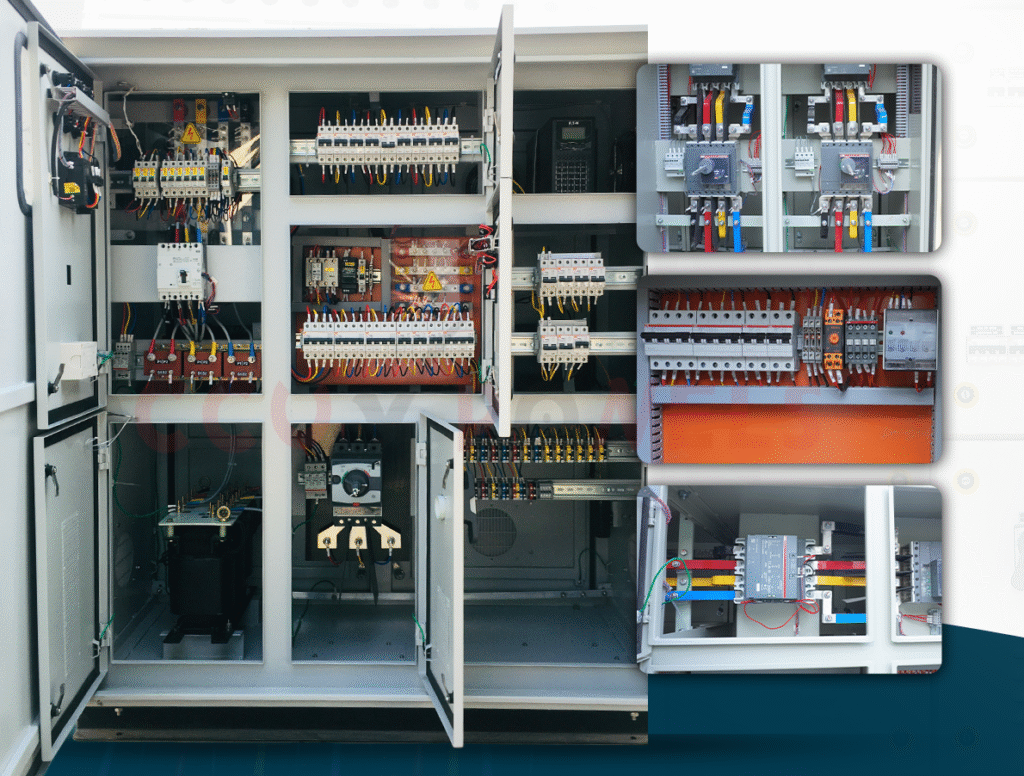

The Busbar Philosophy: Conductive Confidence at 800V LT Panel

At the core of every ACDB panel lies a meticulously designed busbar system, responsible for channeling hundreds of amps of energy with near-zero loss and absolute safety.

Accu-Panels offers copper and aluminium variants:

- Copper Busbars rated at 1.2 A/sqmm

- Aluminium Busbars rated at 0.6 A/sqmm

These are not just bare conductors. They’re fully sleeved, insulated, and spaced to meet short-circuit withstand capacity up to 80kA for 1 second. Every bend, joint, and support is calculated through thermal stress modeling, heat dissipation studies, and IEC creepage guidelines.

Burr-free edges, bolted joints with tin plating, and anti-vibration supports ensure long-term stability—even in dynamic solar parks subject to wind, heat, and vibration. Busbars are color-coded, routed with phase segregation, and laid out in form 3b or 4b to enable safe isolation during maintenance.

CT/PT integrations are positioned with precise burden calculations and shorting link logic to guarantee metering reliability and protection accuracy.

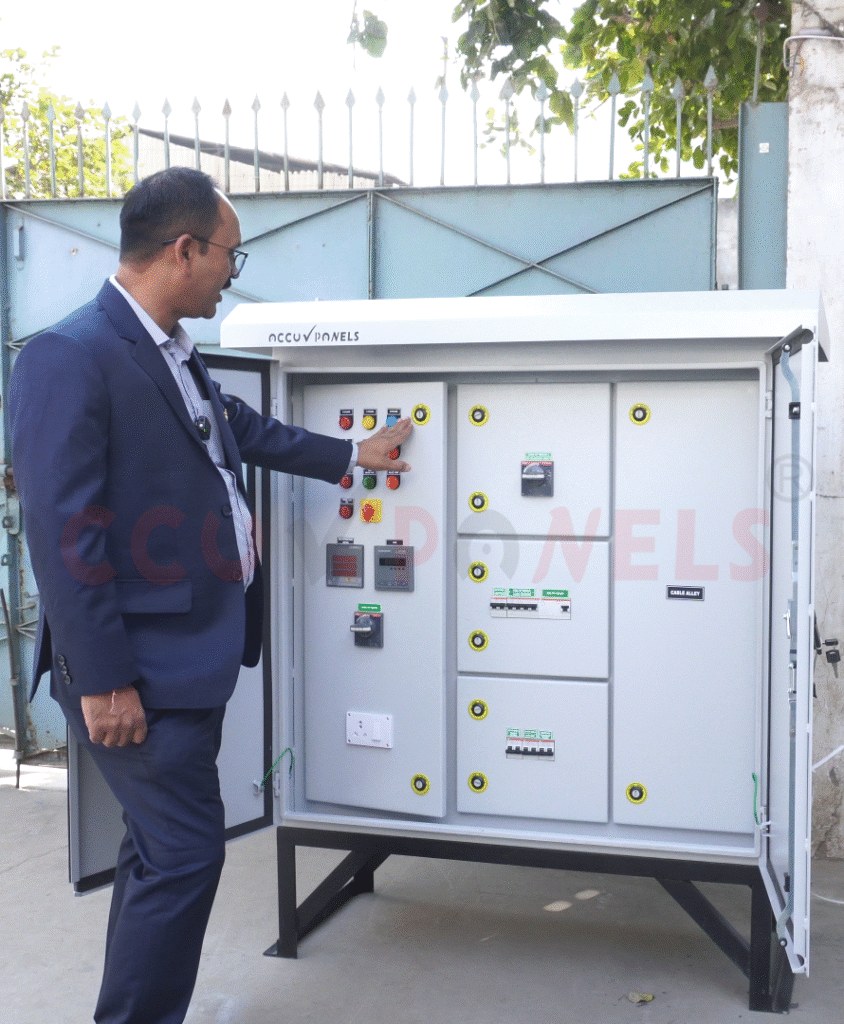

Enclosure Engineering: Where Structure Meets Safety

The enclosure isn’t a container—it’s a guardian. That’s why Accu-Panels’ enclosures are crafted from high-grade CRCA sheet steel:

- 2mm thick for the frame

- 1.6mm for partitions

- 3mm load-bearing structure for incomer supports

- 5mm aluminium/stainless steel gland plate, undrilled & gasketed

Our base frame uses structural steel channels (75mm/100mm) built for seismic zones (Zone V), ensuring the panel remains upright and operational—even during high wind loads or earthquakes.

Ingress Protection is no compromise either—panels meet IP52 for indoor installations and up to IP55/IP65 for outdoor deployments. Every entry point, gland plate, and door is sealed with industry-tested gaskets to prevent dust, moisture, and rodent intrusion.

Surface Coating: Built to Withstand the Elements

Every panel undergoes either a 7-tank or 9-tank C5-grade powder coating process. The result?

- RAL7035 shade that matches EPC branding

- Corrosion resistance for coastal zones, deserts, and chemical parks

- Scratch and UV protection that maintains finish over time

This coating isn’t cosmetic—it’s compliance. It enables the panel to maintain its IP and insulation ratings over a 25+ year lifespan, reducing maintenance and replacement costs.

Height, Access, and Layout Design

Operator ergonomics matter. Our panels are designed to ensure:

- No switch is mounted above 1750mm, keeping operations accessible

- Panel height stays within 2400mm, suitable for containerized or compact rooms

- Mimic diagrams, feeder labeling, and lamp placement follow IS/IEC standards

The modular layout allows future scalability—panels can be expanded, mirrored, or reconfigured based on evolving load profiles or hybrid applications like BESS or EV charging.

Integration Ready: Smart Features Embedded

Busbar and enclosure design support the full electrical ecosystem:

- RS-485 Compatible Devices for SCADA, PMS, and remote diagnostics

- Panel Heaters & Thermostats for thermal and moisture stability

- LOTO Compliance with ON/OFF/TRIP indication lamps on each feeder

- Arc Fault Safety Measures including internal barriers and pressure relief vents

- ROHS-Compliant Materials supporting sustainability and low toxicity

From surge protection to fault isolation, every feature is designed to complement the structural and conductive backbone—ensuring Accu-Panels’ 800V LT panels perform beyond specification.

Conclusion: Why the Backbone Is Everything

In solar distribution, you can’t compromise on the fundamentals. Busbars and enclosures define not just electrical conductivity but fault behavior, system safety, and operational life.

At Accu-Panels, we engineer these elements with precision, compliance, and foresight—ensuring every MW-scale solar project runs smoother, lasts longer, and responds faster to faults.

Because in solar engineering, the backbone isn’t behind the scenes—it’s what keeps the lights on.

Authored By

Ghanshyam Soni Managing Director – Accu-Panels Energy Pvt. Ltd. Ahmedabad, Gujarat, India

Leave a comment