When it comes to MW-scale solar engineering, what happens inside the panel enclosure defines the safety, intelligence, and long-term performance of the entire power system. Accu-Panels’ 800V LT ACDB panels go beyond power collection—they are engineered ecosystems of smart switchgear, multi-layered protection, and remote monitoring capabilities tailored for 1500V DC string inverter solar parks.

Construction That Commands Confidence

Every Accu-Panels 800V ACDB starts with a robust CRCA steel enclosure. The frame is built using 2mm thick steel, the partitions with 1.6mm sheets, and the load-bearing structure with reinforced 3mm supports. Even the gland plates are precision-fabricated in 5mm aluminium or stainless steel, undrilled and fully gasketed to prevent ingress.

Ingress Protection? We’ve got that covered—IP52 for indoor variants and up to IP55 (even IP65 with SCADA integration) for rugged outdoor installations.

Height and ergonomics are also carefully tuned: no switch exceeds 1750mm from the floor, and the overall panel stays within the 2400mm envelope. Panel base frames use 75mm or 100mm channels built with structural steel, allowing seismic and wind resistance even in Zone V regions.

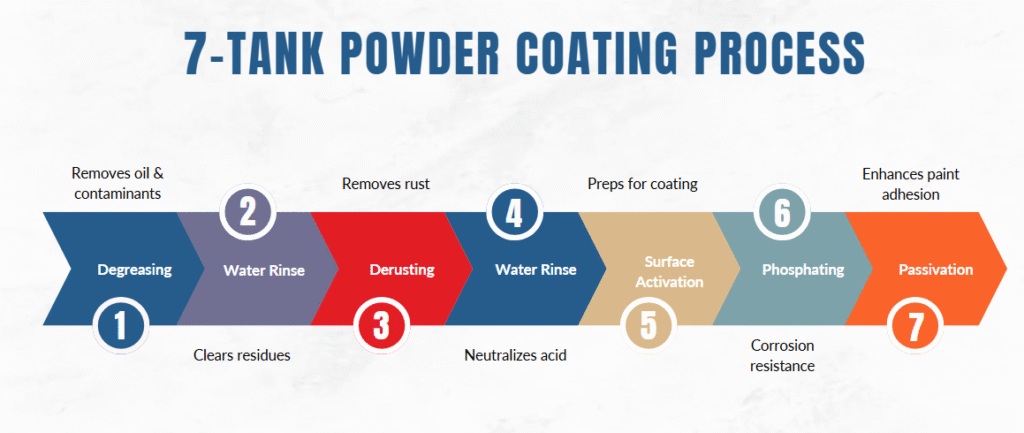

On the inside, the gland plates are crafted from non-magnetic materials and positioned for easy cable access and low thermal distortion. Each panel’s surface undergoes C5-grade corrosion protection using a multi-stage 7- or 9-tank powder coating process—providing a finish that survives industrial zones, coastal air, and harsh climates for decades.

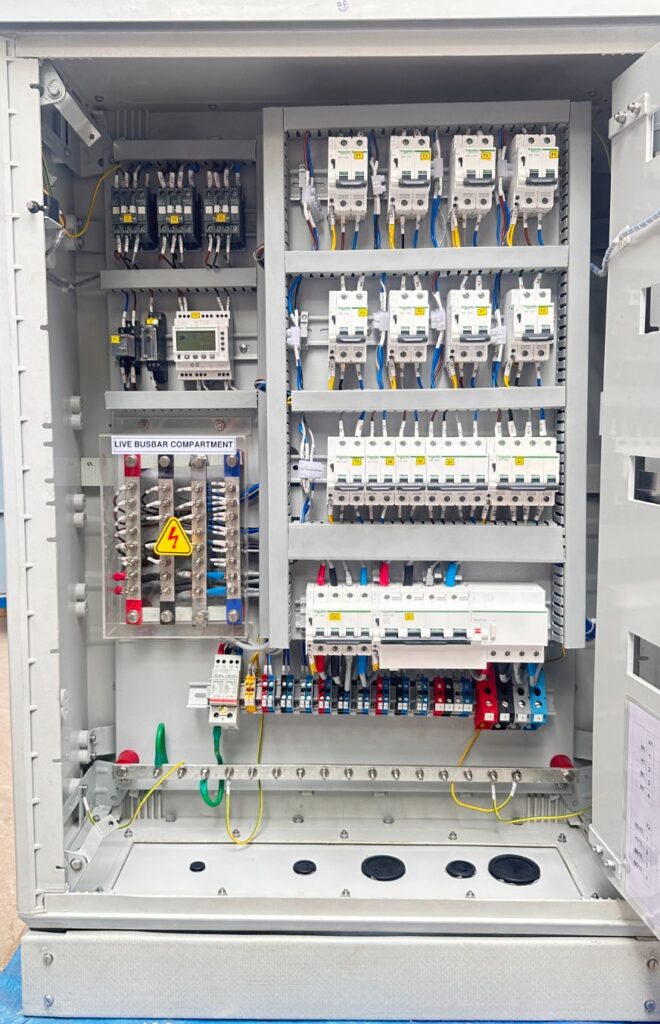

Engineering Inside: Smart Components & Logical Layout

The real intelligence of the panel begins when the door opens.

Busbars—either copper at 1.2 A/sqmm or aluminium at 0.6 A/sqmm—are sleeved, spaced, and aligned with fault withstand calculations up to 80kA for 1 second. The internal architecture follows form 3b or 4b separation, offering compartmentalized zones for isolating faults and protecting personnel.

Metering is powered by digital MFMs with RS-485 output, precision-rated to Class 0.2s. These units feed data into SCADA, EMS, or PMS systems and ensure fault logs, energy audits, and load management are always accessible.

Control lamps for ON, OFF, and TRIP status are positioned for each feeder, forming a clean and intuitive interface that supports lockout-tagout compliance and maintenance protocols.

To maintain thermal and moisture stability, panel heaters and thermostats are installed. They work continuously to fight condensation and keep the insulation systems intact—especially vital in foggy mornings or humid deployments.

Accu-Panels integrates multi-layered protection architecture, starting with precision MCCBs and ACBs. Models like DZ6, DZ7, and OMEGA series offer fault-breaking capacities from 36kA to over 200kA, and are available in both thermal-magnetic and electronic trip versions.

Protection logic built into these breakers includes:

- Overcurrent detection for overload response

- Short-circuit isolation with high Ics/Icu ratings

- Earth fault monitoring via microprocessor-based relays

- Voltage protection that prevents under/overvoltage excursions

- Phase failure detection and unbalance protection

- Reverse power blocking, especially for grid-tied systems

- Arc fault mitigation using either arc barriers or detection sensors

Each logic function is mapped through LSIG curves—Long-time, Short-time, Instantaneous, and Ground fault parameters—fully programmable to match field conditions.

Surge protection is handled through Type 2 SPDs, rated specifically for 800V AC. These devices neutralize lightning strikes, grid disturbances, and transient spikes that could otherwise compromise equipment longevity or transformer safety.

Integration with Smart Monitoring & Remote Control

Protection is no longer reactive—it’s intelligent. Accu-Panels integrates RS-485 enabled meters and relays that allow real-time monitoring, fault diagnostics, logging, and remote tripping. Whether you’re overseeing a solar park from a remote O&M center or syncing load data into PMS software, the panels are fully compatible via industry-standard protocols.

The system also supports hybrid integrations—EV charging, BESS, grid export—allowing EPCs and solar developers to future-proof infrastructure as demands grow.

Validated by Standards, Proven in the Field

Compliance is never just a claim. Accu-Panels 800V LT panels are fully type-tested as per IEC 61439-1 & 2. Internal arc protection is validated up to 85kA for 0.5 seconds under IEC/TR 61641. Earth fault withstand, dielectric strength, temperature rise, and mechanical operation are all verified through Factory Acceptance Tests and witnessed audits.

SCADA diagnostics are simulated and proven. All breakers are tripped and reset under load. And every mimic diagram, CT/PT calculation, busbar layout, and insulation rating is documented.

Each panel arrives field-ready, with internal QAP traceability, third-party certification records, and calibration reports—because engineering isn’t just about building panels, it’s about instilling trust.

Final Thoughts: The Power Is in the Panel

Accu-Panels’ 800V LT ACDBs aren’t just boxes—they’re blueprints of electrical reliability. Every breaker, busbar, plate, relay, and lamp plays a role in securing fault-free power to transformers, grid points, or BESS inverters.

When you open the door to an Accu-Panels assembly, you open a chapter of precision, protection, and purpose.

It’s where compliance meets confidence—and power meets performance.

Authored By

Ghanshyam Soni Managing Director – Accu-Panels Energy Pvt. Ltd. Ahmedabad, Gujarat, India

Leave a comment