Solar ACDB for MW-Scale Projects: Engineering India’s Energy Transformation

India’s transition to clean energy is accelerating, and the backbone of this transformation lies in the engineering excellence of solar ACDB systems for MW-scale projects. While solar developers and EPCs lead on deployment, real innovation happens within the panel design room—where safety, scalability, and compliance converge.

What Makes Solar ACDB for MW-Scale Projects So Critical?

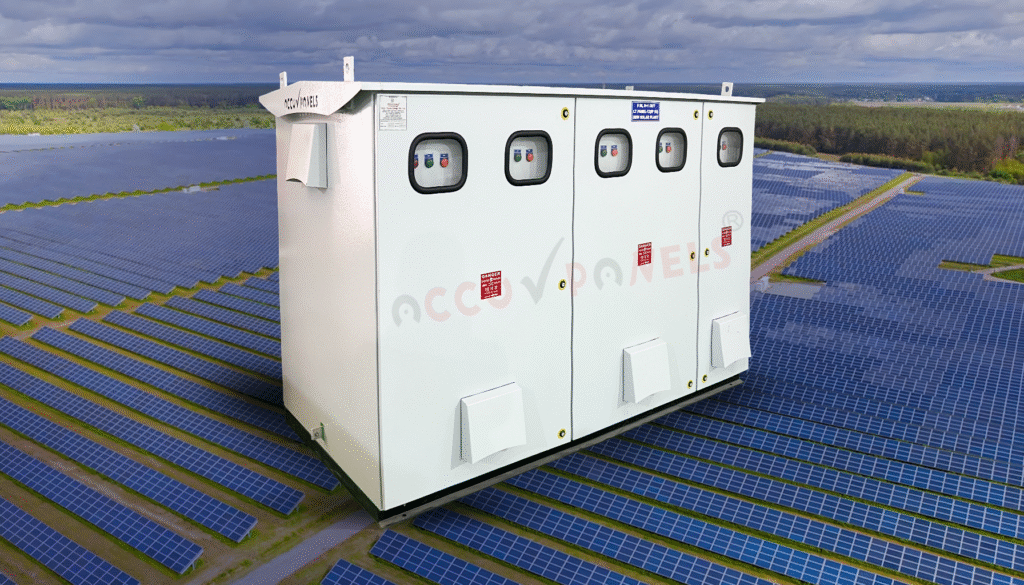

Unlike legacy 415V architectures retrofitted for higher voltages, Accu-Panels Energy Pvt. Ltd. engineers 800V LT ACDB panels from scratch—for the specific challenges of MW-scale solar plants utilizing string inverters.

Engineering Ground-Up, Not Retrofit

While many players repackage legacy 415V architecture to accommodate higher voltages, Accu-Panels starts from a blank slate—designing every 800V panel for MW-scale solar plants using string inverters.

Every inch of our busbar system, breaker selection, enclosure layout, and thermal profile is engineered specifically for 800V operation. That means fault withstand ratings, clearances, CT/PT burden calculations, and metering systems aren’t adapted—they’re purpose-built.

100% Compliance, Zero Compromise

Our panels are not only CPRI-tested, they fully comply with IEC 61439-1 & 2, and internal arc protection is validated as per IEC/TR 61641 up to 85kA.

We don’t just meet specs—we document every calculation, test report, and raw material inspection through our internal Quality Assurance Plan (QAP). That includes HV testing, insulation resistance checks, functional relay verification, and SCADA simulation.

EPCs don’t just get panels—they get full traceability and peace of mind.

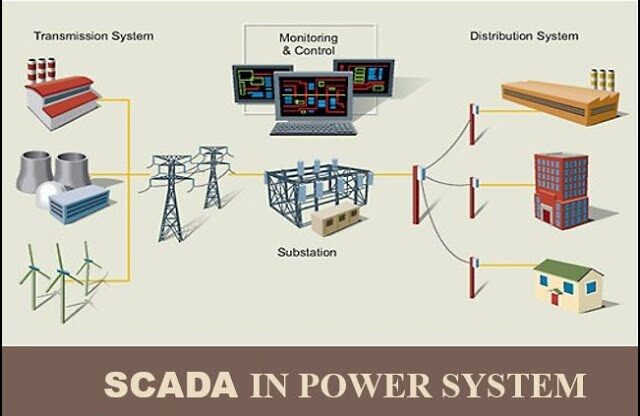

SCADA-Ready, Smart by Design

Today’s solar parks demand real-time diagnostics, remote fault monitoring, and predictive insights. Accu-Panels integrates:

- RS-485 enabled metering

- Microprocessor-based relays

- Trip logic programming

- Energy management system (EMS) compatibility

From grid export to hybrid storage and EV integration—our architecture is ready for tomorrow’s tech.

Rugged Yet Refined: Enclosure Excellence

Built with CRCA steel, reinforced structures, and C5-grade powder coating, our enclosures are designed to survive coastal corrosion, desert heat, and industrial humidity.

Features include:

- Gland plates in 5mm aluminium/stainless steel

- IP55/IP65 ingress protection

- Panel heaters and thermostats for thermal control

No rust, no compromise, no rework.

Thought Leadership, Not Just Manufacturing

Accu-Panels doesn’t just build products—we contribute to the industry conversation. From LinkedIn knowledge articles to technical blogs on 800V standards and OEM partnerships, we’re educating EPCs, consultants, and developers on what quality truly looks like.

We believe compliance isn’t a checkbox—it’s a blueprint for national progress.

Deployed, Proven & Trusted

Our 800V LT panels power utility-scale projects with leading EPCs including Onix Renewable, Torrent Power, and more. These aren’t just products—they’re performance benchmarks across Gujarat, Rajasthan, Maharashtra and beyond.

Field-tested, consultant-approved, grid-integrated.

The Accu-Panels Edge

- Designed for 800V from first principles

- IEC, CPRI and internal arc protection certified

- Modular, scalable and future-proof

- Built for harsh outdoor conditions

- Backed by technical training, QAP, and end-to-end documentation

- Engineered by a team that blends global standards with Indian manufacturing strength

Ghanshyam Soni Managing Director – Accu-Panels Energy Pvt. Ltd. Ahmedabad, Gujarat, India

Leave a comment